UPDATE: WorkSafe have issued a Safety Alert on this

As many of you will know there has been some confusion re having your scuba cylinders tested and filled since a notice was issued on 24th January 2017 by Air Purity Ltd to all dive stores, that have their compressors/filters, etc, audited by Air Purity: Not to test or fill any cylinder that fall into the categories listed.

The Air Purity notice was the result of WorkSafe New Zealand issuing a Hazard Alert on the 23rd December 2016.

WorkSafe were once again (first notice issued 11 Dec 2009) bringing to the attention of the dive industry the international concerns regarding cylinders manufactured from aluminium alloy 6351 which is known to be used in cylinders manufactured between 1972 and 1988. This notice was the result from an incident in August 2016, Sydney, New South Wales, when a Luxfer cylinder ruptured during filling causing serious harm including partial amputation of a leg.

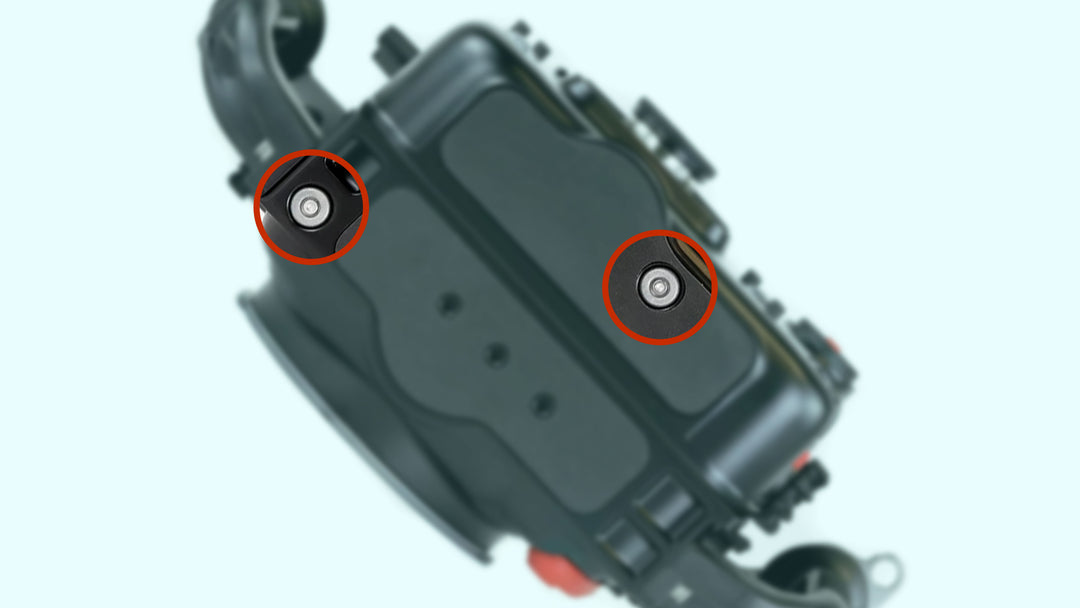

Year of manufacture and specification information is stamped in the neck area of the cylinder. Typically marked as: MM YY or the DOT special permit (SP) or exemption (E) markings. Check your cylinders for the following numbers: DOT; SP6498, E6498, E7042, E8107, E8364, E8422.

WorkSafe have not yet banned the filling or testing of these cylinders. Note in their notice re suspected cylinders they add: “but not limited to” these types of cylinders. WorkSafe have reinforced good practice procedures for preventing failures. Also noted is that a cylinders working life not exceed 15 years which is recommended by some cylinder manufacturers.

Dive stores that are audited by IANZ (International Accreditation New Zealand) have continued to test and fill cylinders that pass their testing procedures. But as many divers have discovered if they try and have their cylinder filled at a non-IANZ store their cylinder will not be filled. There is a very strong rumour that WorkSafe will soon issue a Notice advising all auditing agencies to advise their customers (dive stores) not to test or fill certain cylinders.

The cause for these ruptures is mainly due to sustained load cracking (see the Wikipedia entry here). These cracks develop over time as a result of the cylinder being subjected to high pressures for prolonged periods of time. Many divers have cylinders filled to 3000psi/200bar and stored for many months without giving them a second thought.

It is highly recommended even if your cylinders are not currently identified in the list above, to only store your cylinders with pressure of around 500psi/35bar or less. Do not store your cylinder without any pressure (empty) as this can cause moisture to enter the cylinder. The oxygen content in your cylinder can also drop below 21% over time due to internal cylinder corrosion. Check your cylinders NOW!

This article was also published in Dave's Editorial in the 158 June/July 2017 issue of Dive New Zealand & Dive Pacific magazines.

Leave a comment